LC Magna

メーカー : Photocentric

造形方式 : LCD

主な使用材料 : Draft、Durableなど

材料の形状 : 樹脂(液体)

造形サイズ : 510 x 280 x 350 mm

価格 : お問い合わせください

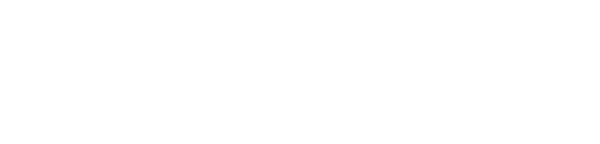

PhotocentricのLC Magnaは、510 x 280 x 350mmの大きな造形エリアをもち、高速で高精度に大型サイズの造形と大量生産を実現します。特許取得済みの「Blow-Peel(ブローピール)技術」を備えているため、安定した造形が可能。試作や、歯科用アライナー、自動車部品、フィギュアなど、さまざまな業界・用途に対応しています。

製品説明

【LC Magnaの特徴】

- 510 × 280 × 350 mmの大型サイズの造形が可能

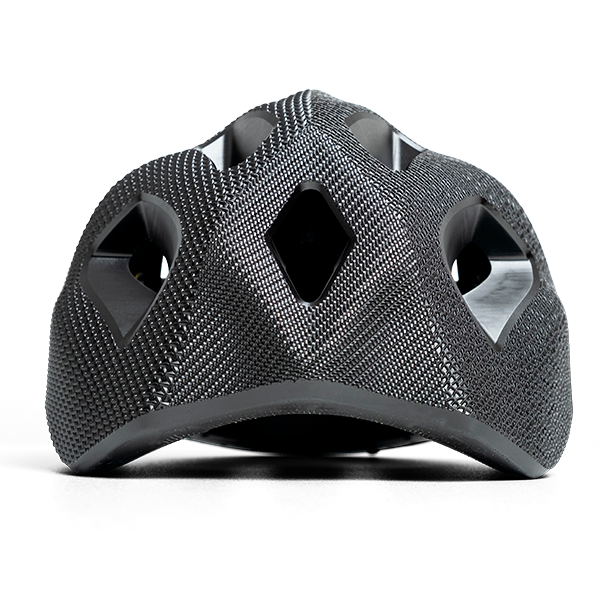

- SLA方式に比べて造形速度が速く、1時間当たり最大16mmの高さで造形できるため、大量生産に最適

- 安価な樹脂と少ない消耗品交換で運営費を最小限に抑えることが可能で、従来の射出成形と比較しても、価格面は非常に優れている

- 専用の樹脂クリーナーは、IPAに比べてより高い性能を出すことができ、また不燃性のためより安全で快適に使用が可能

【Blow-Peel(ブローピール)技術】

ブローピール技術とは、LC Magnaに採用されている特許技術です。光造形方式3Dプリンターの問題は、造形物がベッドだけでなく、材料を入れているバットにもくっついてしまい、造形が失敗してしまうことです。次の硬化サイクルに備えて、新しい樹脂を入れるためには、造形物を持ち上げてバットの底面から離す必要があります。 以下の動作により、造形物をきれいに引き離すことができます。

- プリント層の材料が硬化

- エアポンプでバットの下に空気を送り込み、バットフィルムと液晶を分離させる

- バットフィルムとスクリーンの間のポケットから空気を抜き、次の層の準備をする

【LC Magnaのワークフロー】

- Photocentric StudioにCADファイルを読み込み、数クリックでプリントの準備ができます。

- Blow-Peel(ブローピール)技術を用いて、1層ずつ安定した造形を実現します。

- 造形された部品を洗浄し、余分な樹脂を取り除きます。

- 部品を硬化し、使用できる状態にします。

【Photocentric STUDIO】

専用ソフトウェア「Photocentric Studio」で、造形データを作成します。非常に多くのCADフォーマットに対応しており、効率的な生産を手助けする多くの機能を搭載しています。

- 生産性の向上:自動バッチ処理により、プラットフォームを最大限に活用することができます。また、3Dモデルの向き、移動、スケーリング、コピー、ミラーリングを自動および手動で行うことが可能です。

- 最適化された自動サポート生成:最適化された自動サポート生成アルゴリズムを提供し、ソフトウェアの準備時間を最小化します。超高速マルチプロセッシングによる自動化機能です。また、樹脂の種類や部品の形状に応じて、あらかじめ設定されたサポートプロファイルを搭載しています。

- 重要なサポートエリアの自動検出:自動解析ツールにより、サポート構造が必要な箇所を特定します。また、大容量の造形物に対応するため、マルチプラットフォームを備えています。

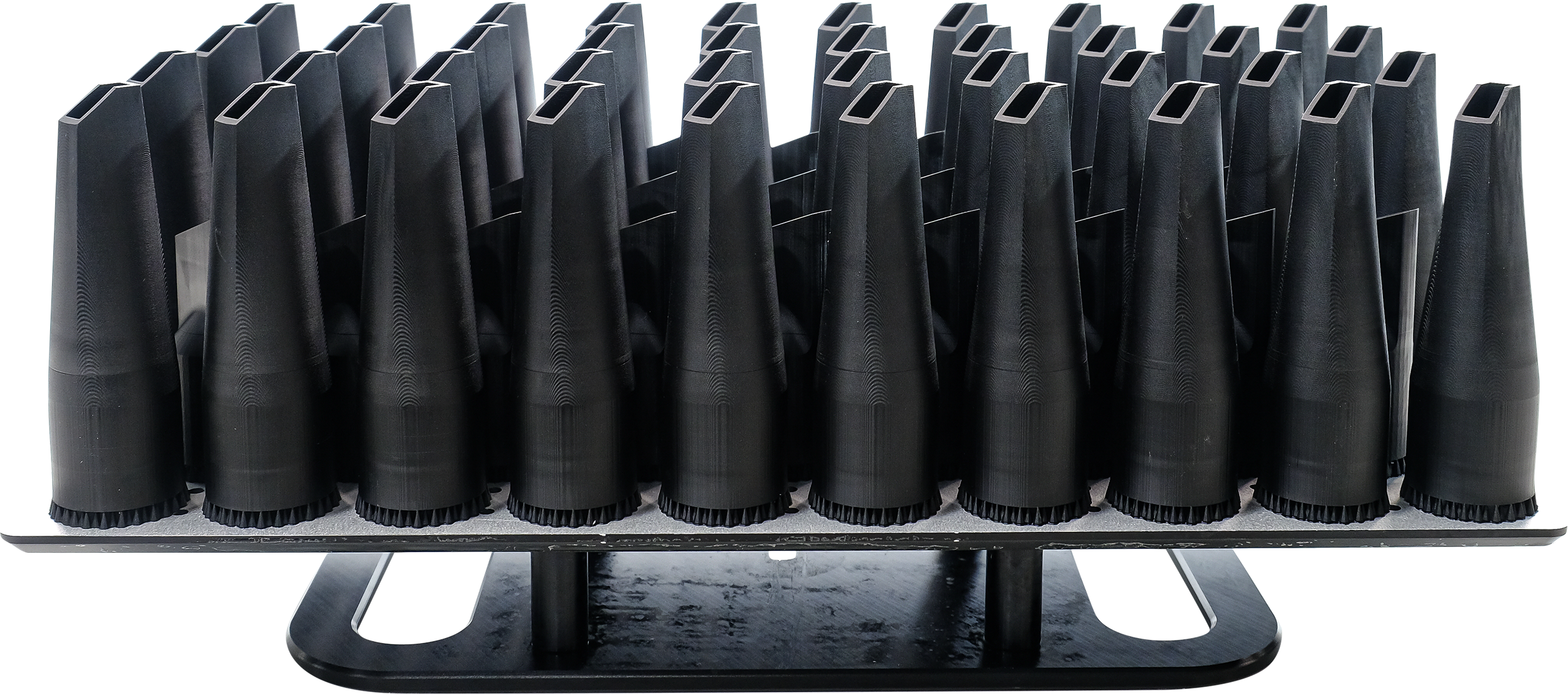

- ドレインホール、くり抜き、インフィル:樹脂の使用量を減らすために、ドレインホール、くぼみ、インフィルなどのモデルを最適化することができます。成功率の向上、材料の節約、軽量化が可能になります。

【2STEPの後加工】

材料の特性を最大限に引き出す付帯装置 LC Magnaには、洗浄装置「Air Wash L」と硬化装置「Cure L2」がセットになっています。洗浄装置で余分な樹脂を効率よく除去し、硬化装置で造形物を強化することで、より高い品質を実現します。

Air Wash L

- 大量生産用に設計されており、空気撹拌システムと樹脂クリーナーを使用することで、効果的に洗浄することが可能

- 90Lの洗浄ユニット

- セットアップが簡単でユーザーフレンドリー

- 数100万個の気泡が造形物に接触し、徹底的に洗浄

Cure L2:

- ビルドプレートを光と熱の両方で効果的に硬化させることが可能

- デジタルタイマーによる操作で、材料によって異なる硬化時間も簡単に設定が可能

- 二次硬化で仕上げることによって、材料の特性を最大限に引き出す

【Photocentric の樹脂クリーナー】

Photocentric の樹脂クリーナーは、Photocentricの機器で造形した部品を最適に洗浄できるように開発されています。専用の樹脂クリーナーを使用した部品は、複雑な形状や手の届かない隙間もきれいに洗浄することができ、IPAでの洗浄に比べて表面を非常にきれいに仕上げることが可能です。また危険物に該当せず、交換の頻度も少ないため扱いやすいです。

VIDEO

製品詳細

製品名

LC Magna

メーカー

Photocentric

国名

イギリス

造形方式

LCD

本体サイズ

850 x 650 x 950 mm

本体重量

110 kg

使用可能材料と形状

・Dental Model

・Hard

・Draft

・High Temp DL400

・Rigid DL240 Plant-Based

・Durable

・Duramax

・DL110H

・Flexible DL220B

・BASF社製材料一部

ノズル径

‐

積層ピッチ

0.025 - 0.3 mm

造形速度

16 mm/h

電源

110 - 240VAC、50/60Hz

消費電力

最大1300 W

スライサーソフト

Photocentric Studio

TDSダウンロード